| Model | STD-80 | |

| Capacity | pcs/min | 70-80 |

| Size Range | mm(max) | Top diameter:Φ100, Height:220 |

| Suitable Paper Thickness | gsm | 135-450 |

| Sealing Method | / | Ultrasonic and hot air system |

| Running Power | KW | 12 |

| Air Compressor | / | 0.4m²/Min. 0.5MPa |

| Net Weight | Kgs | 3400 |

| Machine Dimension | mm | 2500*1800*1700 |

|

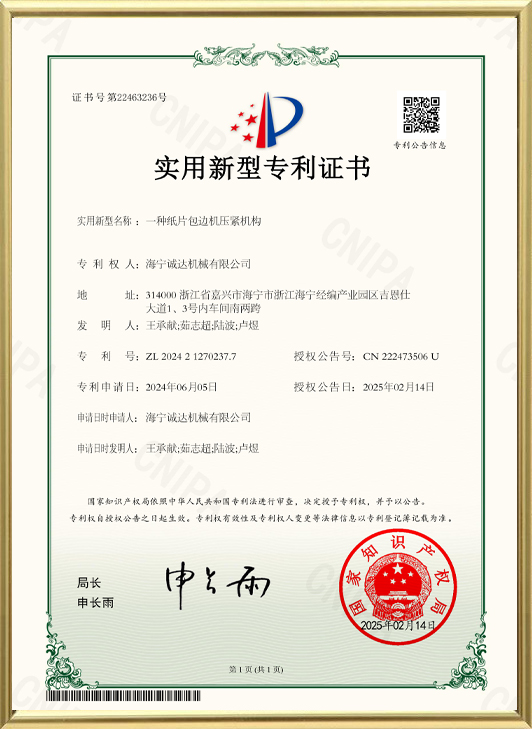

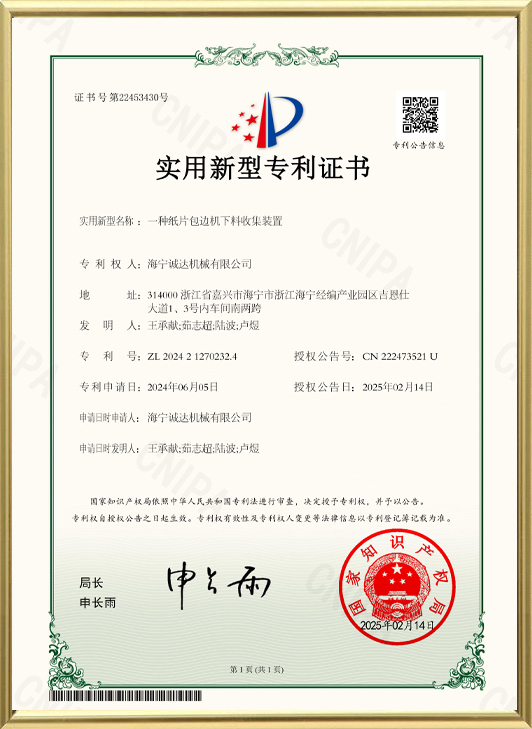

Established in 1998, Haining Chengda Machinery Co., Ltd. is a professional Wholesale Cylinder Paper Cans Making Machine Manufacturers and STD-80 Paper Tube MachineSTD-80 Paper Tube Machine Factory. We have R&D, production and sales department. After 20 years of hard work, our company has a strong technical team and a research and development center cooperating with Taiwan's senior paper container molding technology team and obtaining national patents such as a straight tube machine. Our company has modern assembly workshops, precision parts processing workshops, training centers, QA centers, and other infrastructure. Our company has CE, ISO9001 certification system, and national import and export rights.

In recent years, based on the characteristics of Chinese paper and the development trend of paper containers at home and abroad, we have developed a batch of international synchronization technology units of the intelligent molding Machine with automatic detection systems and remote connection systems for paper cup machine, paper tube machine, paper lid machine, doner box machine, etc.

-

What equipment is required for a complete production line of paper cup manufacturing?

What equipment is required for a complete production line of paper cup manufacturing?Production Flow: Raw Paper Roll → Printing → Die-Cutting → Cup Forming → Inspection → Packaging Output: 150,000–600,000 cups/day Cup Size: 5–22 oz ( Single wall cups) Key Equip...

-

The Ultimate Guide to Paper Cup Food Container Machine: Production, Selection, and Optimization

The Ultimate Guide to Paper Cup Food Container Machine: Production, Selection, and OptimizationUnderstanding the Role of the Paper Cup Food Container Machine in Modern Packaging The Paper Cup Food Container Machine stands at the forefront of the disposable packaging industry...

-

The Comprehensive Guide to Modern Double-Wall Paper Cup Manufacturing Technology

The Comprehensive Guide to Modern Double-Wall Paper Cup Manufacturing TechnologyExploring the Core of Insulated Cup Production Machinery The manufacturing of double-wall paper cups represents a sophisticated segment within the paper container industry, requiri...

English

English عربى

عربى 中文简体

中文简体